Techniques for DIY Screen Printing on Glass

View EZScreen products that work on glass.

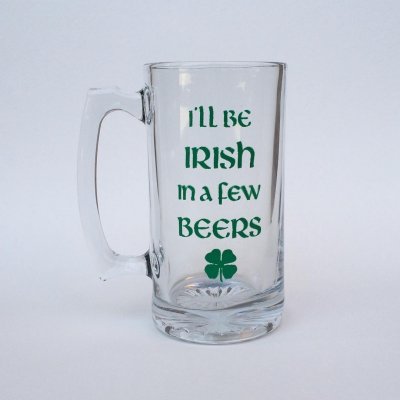

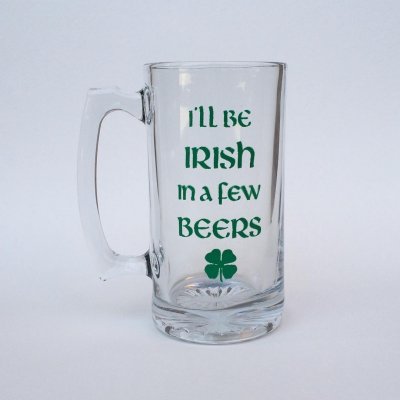

EZScreen DIY silk screen stencils can work on a multitude of surfaces, including curved surfaces like glass, plastic, and metal. After creating glass projects ourselves, we realized that not all glass paints are created equal, and there are certain techniques that help the project turn out better. Here are some of our suggestions when screen printing on glass:

1 - The type of paint matters

- We went through multiple brands of glass paint and came to the conclusion that Liquitex Professional Acrylic Paint work the best and can be found relatively easily. Other store brand acrylic or enamel paints will leave bubbles or bleed under the stencil during printing. However, we had the best results with Liquitex.

- Color Line paints and pastes are the best professional grade enamels for screen printing on glass. These glass paints require firing and are used by artists for their high pigmentation.

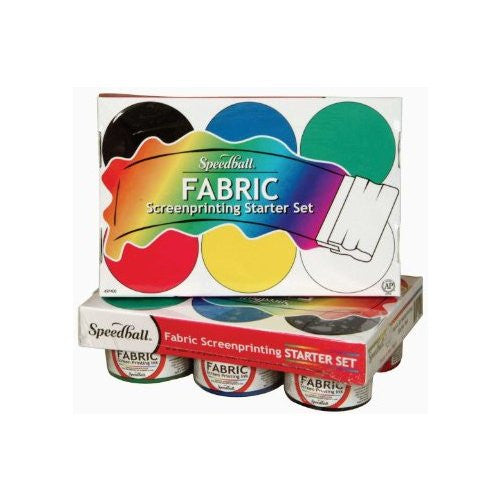

- Another tip is mixing Speedball screen printing ink with store bought acrylic or enamel glass paints. Somehow, adding Speedball ink eliminates bleeding issues than just using the acrylic or enamel by itself. But by doing this, the ink/paint combo will not be permanent on the glass surface and will require a clear coat to seal it in.

2 - Use a brush or soft squeegee

- When applying the paint on a curved or hard surface, we recommend using an artist brush. A regular squeegee may be too rigid. Other customers have found using a soft squeegee worked well for them. Everyone develops their own preferences and techniques depending on the project.

3 - Use spray adhesive

- It is extremely important for the stencil to have complete contact with a glass surface during printing. If the stencil is dry, then the paint will bleed and the results will not be pretty. Apply a light spray of the repositionable glue on the underside of the stencil and rub away any air bubbles once placed on the glass surface (we found Aleene's Repositionable Tacky Stencil Spray to work well). After printing with glass paint, remove the stencil immediately and place in a bucket of water or wash off in the sink. The stencil will remain tacky if repositionable stencil spray is used.

- Be sure to use a tacky spray that sprays a light mist. If the spray comes out chunky, it could clog the screen and block the paint from passing through the stencil.

4 - HiDef EZScreen stencils

We recommend using HiDef emulsion stencils when printing on hard surfaces, especially glass. The higher mesh count in the high definition stencils are less visible than the more open mesh in the Standard stencils. Because HiDef screen print stencils have a higher mesh count, you can achieve more detail in your designs. Choose between our Basic Starter Kit with HiDef stencils, or our Mini Starter Kit with smaller HiDef screens.